Already used for fuel production during the Second World War and the various oil shocks that have occurred since, methanisation is an interesting technology for the energy transition, which allows the production of energy from organic waste.

It was quite by chance that I made my first visit of this tour of Europe to the methaniser of Sommerance (Ardennes, France), operated by the organic farming company GAEC Pierson since 2016.

The purpose of this article is to explain the general operation of this type of installation, providing details specific to the type of installation set up in Sommerance, and raising the basic problems related to methanisation.

How does it works ?

Methanisation is a process of decomposition of organic matter by bacteria without oxygen. This technology makes it possible to produce a fertilizer called the “digestate”, as well as a gas composed of 50 to 70% methane (CH4) and carbon dioxide (CO2) that can be exploited in two different ways: by cogeneration, that means energy production and heat generation; or injection, biogas production.

In order to feed the methanisation process, fresh organic matter, which is in the case of the Sommerance methaniser, must be continuously brought in in the following proportions:

- 80% agricultural waste: manure and slurry from cows, and small straw from crop harvest.

• 16% agro-industrial waste: vinasse (beet), potato starch, onions, etc.

• 4% corn, stored since the creation of the methaniser and used to offset uncertainties related to the supply of agro-industrial waste

It is also possible to use other sources of organic matter such as municipal waste: grass clippings, organic waste, sewage plant sludge and grease, etc.

Management of Methaniser Performance:

Managing the performance of the facility is an important issue for the operator.

First of all, the process of methanisation in the digester requires a launch time of 140 days before reaching a maximum yield. It is therefore important to maintain this yield, so as not to suffer too long a loss of production. The installation is thus made to allow the process of methanisation to be carried out even in the event of maintenance or damage, even to burn the surplus gas produced in these cases.

In addition, this type of very expensive facility often requires a bank loan. In the case of the Sommerance methaniser the initial investment exceeding EUR 1 million, the need to repay the loan under 15years add another obligation of productivity which justify the yeilds value

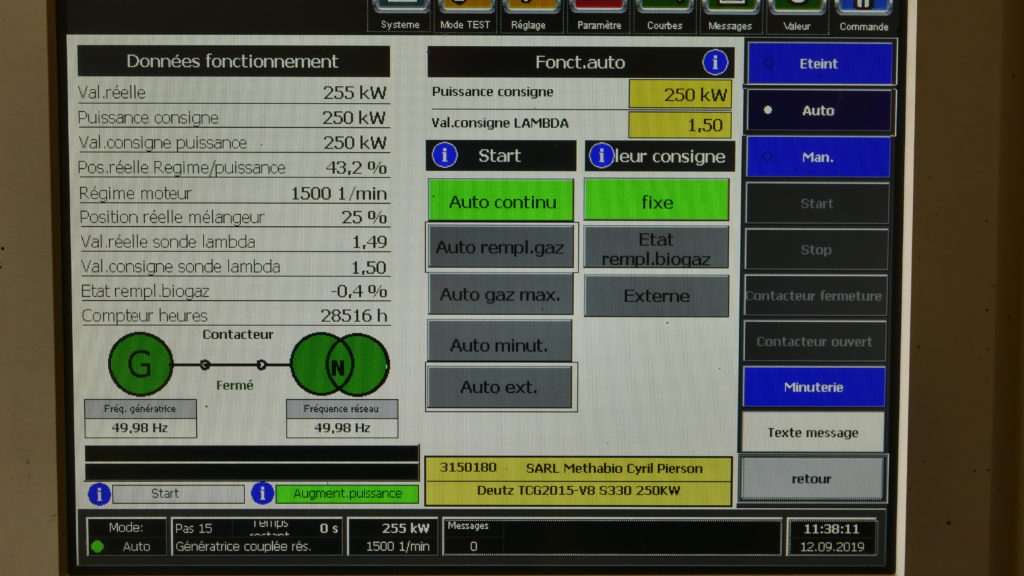

This means that the operator must constantly ensure that the methaniser is operating properly. A station dedicated to the maintenance and management of the installation has therefore been set up in Sommerance.

The critical points for the performance of the methaniser are: the determination of the injected organic matter, the good homogenisation of the material in fermentation, the monitoring of the proportion of sulphur in the biogas, verification of pressure and pH in the vessels, and maintenance of the cogeneration engine.

The management of a methanisation facility therefore requires operators to acquire new technical and scientific skills, in particular to understand as best as possible the reactions involved in the methaniser.

Management of Methaniser Safety:

Handling large quantities of gas obviously raises safety concerns. However, the handling and storage of the gas is carried out at pressures too low for an explosion hazard to be considered, which greatly reduces the safety problems of the station.

In order to keep the gas at these low pressures, several equipments are provided on the installation.

A gas flare is thus provided at the gas line connecting the digester to the post-digester. It is used to consume gas in case of overpressure in the digester or after digester unavailability (breakdowns or maintenance).

The two tanks (digester and post-digester) are also equipped with valves allowing some of the gas to be evacuated in the event of excessive pressure in the vessels and the gas flare not being available.

A central room at the installation allows to manage the material flows between the different vessels, thanks in particular to a central pump. The equipment in this room is designed to simplify damage management and safe site maintenance.

The operator is also capable of controlling all methaniser units remotely from a computer. In this way, it can be warned in the event of a malfunction or malfunction, and respond quickly without having to be always present on site. An alarm is also activated on the operator’s laptop to warn the operator at any time of such damage.

A central room at the installation allows to manage the material flows between the different vessels, thanks in particular to a central pump. The equipment in this room is designed to simplify damage management and safe site maintenance.

Precautions for the dimensioning of a methaniser:

The integration of a methaniser into the operation of a farm is therefore very interesting, although it must be dimensioned in line with the capacity of the farm.

One of the main criticisms of methanisation facilities is their dependence on external and uncontrollable organic matter. Indeed, if a facility is oversized and does not receive enough organic material, the operator is obliged – to maintain a good process performance – use sources of organic matter normally intended for food use, such as maize.

Unfortunately, there are also operators who choose from the beginning of the project to run their methaniser with a majority of corn

The use of such sources of organic matter is totally inconsistent with the desire to produce so-called “renewable” energy through waste recovery.

In the case of the Sommerance plant, maize represents only 4% of the organic material used. This maize has been stored since the introduction of the methaniser, and helps to offset the uncertainties associated with the supply of agro-industrial waste. This low proportion therefore does not detract from the good consistency of the project.

- Fécule de pomme de terre provenant de l’industrie agro-alimentaire.

- Fumier stocké avant l’intégration dans le digesteur.

Another important factor to be taken into account when designing is the area of fields to be applied. The objective is not to produce more digestate than is necessary, or not to be dependent on the import of fertilisers in case of underestimation of the quantity required. This point is less critical than the previous one, and depends on the objectives of the operator vis-à-vis his autonomy.

A third point to be considered upstream of the construction of the methaniser is the evaluation of the possibilities of valorizing the energy produced. This point is important for choosing between cogeneration or injection (biogas production), and in the first case allows the optimization of the heat produced.

Finally, the integration of the structure into the landscape is a point not to be neglected. Provisions at this level may even be required by the DRAAF, in order to limit the distortion of the rural landscape and not to alienate the inhabitants of the territory.

The operators of the Sommerance methaniser decided to bury part of the 6-metre-high tanks in the hill on which the site is located. Trees were also planted in front of the vats in order to hide them from the view of the inhabitants of the hamlet.

It is also preferable to warn the inhabitants before the implementation of the project, in order to reassure them about these issues of integration in the landscape and smells, but also safety. It is also possible to organize an open door day to open the methaniser so that the inhabitants really understand the issues of the project.

Methanisation in France

Between 2011 and 2013, 242 projects – all sectors – were identified by ADEME, representing an estimated primary energy production of 3,069 Gwh (biogas, electricity and heat)0.1% of French primary energy consumption in 2017.

However, the number of ongoing projects continues to increase. Thus, ADEME even advances that ‘assuming the installation of 600 methanisers per year by 2030 (almost twice as much as in Germany), the primary deposit available is 6 Mtoe in 2030, with about 50 % for final use in the gas network, 30% for cogeneration and 20% for direct heat use.

With these figures the sector would thus reach 2 to 3% of French primary energy consumption, if it does not increase in a significant way by then

How to fund this kind of project ?

The purchase price for electricity from a methanisation plant is currently €0.21/kWh, compared to around €0.14/kWh for the retail price (prices valid for EDF).

Aid has also been set up by the State, such as the “Fonds Chaleur” managed by ADEME, which supports the financing of energy recovery projects and the production of heat from renewable energy sources.

This preferential tariff and this help enable operators to make a faster return on the investment made to build the plant and thus encourage the development of this sector

Methanisation: a very promising energy source, which still raises many questions

Methanisation is a fast-growing energy sector with good prospects for development.

This technology has a dual interest in the recovery of agricultural and industrial waste and in the production of energy. It allows farmers to diversify their activities and gain energy self-sufficiency – especially through the exploitation of heat.

The interest of methanisation is also to allow, like most renewable energy sources, the decentralization of energy production. In fact, it gives rural areas a new control – partial but not negligible – of their primary energy production.

This energy source is all the more interesting, since its production is low polluting, in comparison with the fossil energies still mainly used in the global energy mix. In addition, since methanisation allows local production of electricity, heat and biogas, it would be interesting to quantify the energy savings made on the transport of raw materials, in relation to the use of fossil fuels.

Methanisation therefore seems to have all the assets to be an energy of the future and contribute to the energy mix of tomorrow. However this article is far from answering all the problems raised by this technology, and some questions still need to be studied:

- What is the impact of using this new fertilizer digestate on agricultural land?

• What is the environmental and health impact of methane combustion, in terms of CO2 and fine particulate matter emissions?

• Is the large-scale development of methanisation consistent with reasoned agriculture and a decline in beef production?

These issues are complex to address and require further research.So I would encourage you to do some research on your own, to feed into the energy transition debate.